|

NAT ► Senercomm ► Onity Hotel HVAC Energy Management System |

|

Electronics Engineering Career (page 2) |

|

I answered a tiny ad in the Palm Beach Post Times newspaper (see photo inset). It turned out to be a small start-up company getting into the hotel HVAC energy management business. Mark, the founder, already had the concept of what he wanted based on his experience with similar products. The basic idea was to detect when no one was in the hotel room and “setback” the temperature to save power until the guest returned.

I went to the meeting with my resume and took along my “Organizer” which I had recently built (will put this in my Magazine Articles & Early Projects section at some point). I discussed everything I had designed, showed him my “Organizer” and explained that I had a pretty nice lab at home where I could easily develop his product. He gave me the job to develop a working prototype. Little did either of us know that this would go on for 18 years (until Dec 2007)!

Fortunately, I had just finished designing an information display for my DeLorean. This was my first project using the new Motorola 68HC705 µC. It also involved reading temperature sensors which I placed at various places in the car. What a perfect starting place for this project!

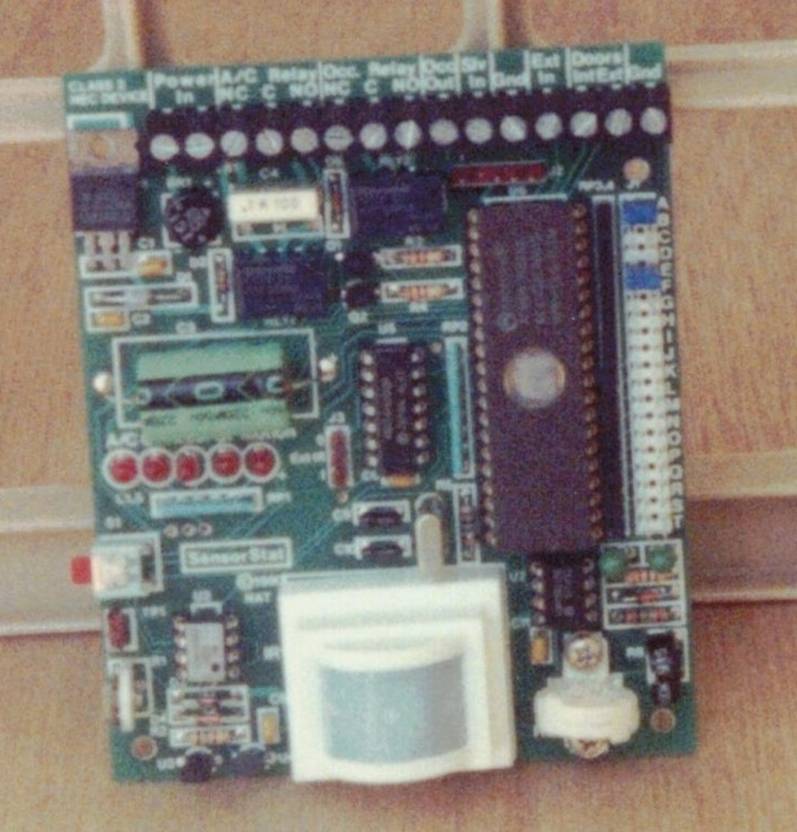

The first SensorStat was powered by the HVAC’s 24VAC transformer. I used 2 small relays to send that 24V back to the HVAC as control signals. The unit had a large terminal block at the top for I/O, a 5VDC power supply, some LED indicators for setup and diagnostics and a large bank of jumpers along the right edge for all the various settings & options.

There’s also the temperature sensor and it’s A/D. You could order the optional humidity sensor with it’s circuitry. I had it create a pulse train where the frequency depends on the capacitance of the humidity sensor. That allowed the µC to calculate the humidity. There was also a PIR motion sensor module.

While designing the unit, I realized that there was no provision for communications at all. I suggested we include a connector for possible future use, and since it didn’t cost anything I was told to go ahead. This would indeed foreshadow the future where communications ended up being almost as important as the basic functions.

As time went on, instead of being an aux. unit that overrides the thermostat, we moved into making the whole thermostat. Over time I designed units with green LED 7-segment displays, general purpose numeric LCDs and finally dedicated custom LCDs. See photos below.

At some point, the units had so many operational settings and options it exceeded the number of selection jumpers that could reasonably be put on the PCB. I designed a “Handheld Programmer” (see b&w photo down the page) which had an LCD screen and 4 soft-switches. It plugged into the Sensorstat and communicated serially. It would lead the installer through many menus of selections then send them to the Sensorstat which would put them in non-volatile memory.

System communications started with a small adapter board I made with an RS485 transceiver. We created a wired network which could be installed in the hotel, allowing total control from a head end PC. The power of communications opened up a myriad of possibilities. It became just as important as the original simple goal of saving power. The trouble was that wiring a hotel with differential signal cables was pretty overwhelming and not possible in a lot of locations.

That led us into RF communications. We ended up creating an RF network between all our units and the front end, with repeaters, etc. This even extended to the thermostat. I designed a unit that was battery powered and communicated wirelessly to an “RFRCU” control unit which resided in or near the HVAC. It would execute the actual control based on occupant input, temperature, motion and other data from the thermostat.

|

|

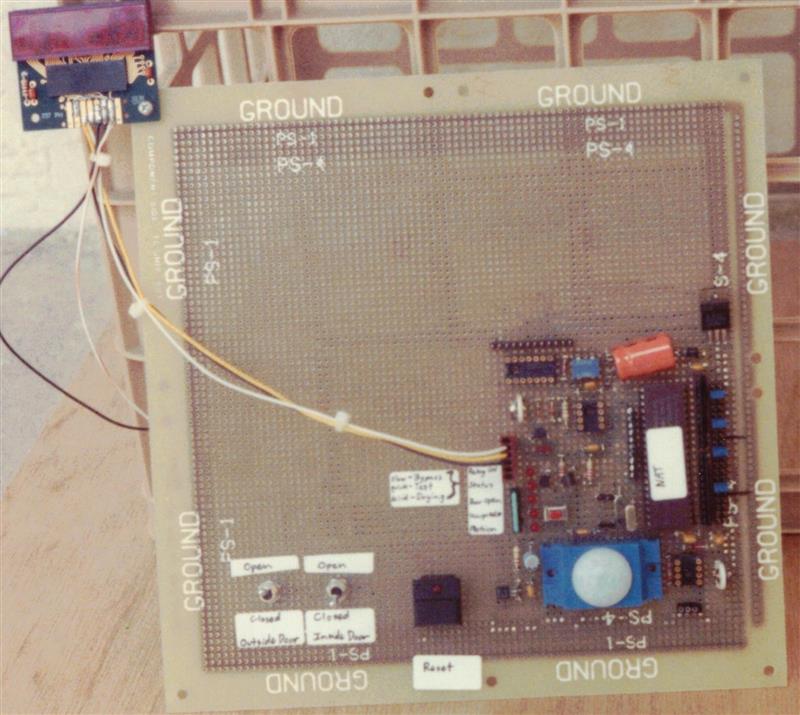

Handwired prototype completed & working. |

|

First PCB assembled. |

|

Slightly later version of the first SensorStats ► |

|

Small ad in newspaper I answered. |

|

RFRCU |

|

Tourisafe - Hotel Room Safe |

|

This is really the last product I developed in my formal career. I worked for startup Lumewave from Oct 2009 to May 2014, so about 4.5 years. Their concept was for an intelligent street light controller, mainly to save energy. They were working with researchers to establish how much energy could be saved by turning off streetlights under central control when roads were sparsely populated rather than having them simply come on at dusk and off at dawn.

Given the goals and physical parameters of the twist-on controller housing at the top of the streetlight, I did all the electronic design, PCB layout and firmware for their products. It evolved into a rather complex controller, with a proprietary RF network protocol. Units would also act as repeaters to build out the network over a large area, such as down a highway. It can be reprogrammed over the air from the central office. Later versions incorporated billing-accurate energy-use measurement recording and reporting capability.

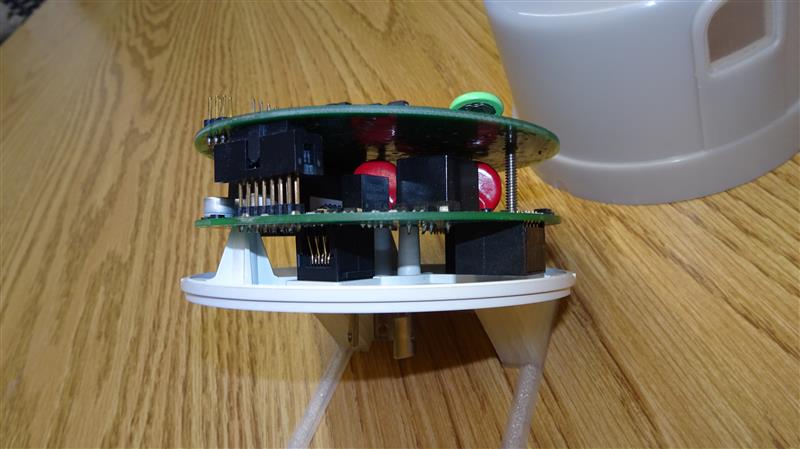

There were many versions as capability was added. Lots of accessories such as a GPS programmer. The unit has two stacked round PCBs. The bottom one is the power supply board with power measurements. The top board is the controller, with a 9S08QE128 µcontroller, non-volatile FRAM, real time clock, etc. I think Echelon owns Lumewave now.

|

|

GPS Programmer |

|

Lumewave Wireless Street Light Controller |

|

I did an interesting project for a company that wanted a new design for hotel room safes. They already had the safe and bolt mechanism so they hired me to design the electronics. I used EEPROM non-volatile memory to keep a rather deep set of root numbers containing all the various levels of security codes. The design had to be battery powered, scan a keyboard, look at µswitches and drive a motor. I created a little H-bridge with transistors to drive the motor. One important aspect was to draw as little power as possible form the battery until a keypad button was pressed, which I accomplished with more transistors. It was a great project. I wish I had a brochure for it, but I did find these photos on the web. |