|

I had a friend in the music equipment business. Somehow, he met a teacher who worked with speech impaired kids. Stuttering was being treated with Delayed Auditory Feedback. The subject would wear headphones which blocked outside audio and would speak into a microphone. They would only hear their own speech after it was delayed. Adjusting this delay would have the effect of slowing down the speaker and letting them learn how to pace themselves and reduce stuttering.

The equipment made at the time to perform this task was very crude yet expensive. Also, PCs were not very powerful. They used most of their processing power to run the video output and had little to offer in the way of high quality audio, mixing, etc. They were also very expensive.

We started putting together a set of functions that would be good to have in a new, more powerful machine. The main functions were based on what the profession considered the most useful at the time. We also put in a lot of things that we thought might be good for experimental purposes in addition to some fun things that we thought might help hold the interest of the principal patients, which were children.

I thought if we were really going to do this, I would design what would be a very powerful machine (for that time). I had just designed my Dictaphone Express Talk dictation system around the 68000 µP. This was the same processor used in Apple’s then-new Macintosh. We would have a simple 2-line by 20 character LCD display with a handheld keypad as a user interface. This allowed me to dedicate all the processing power of the 68000 to manipulating audio.

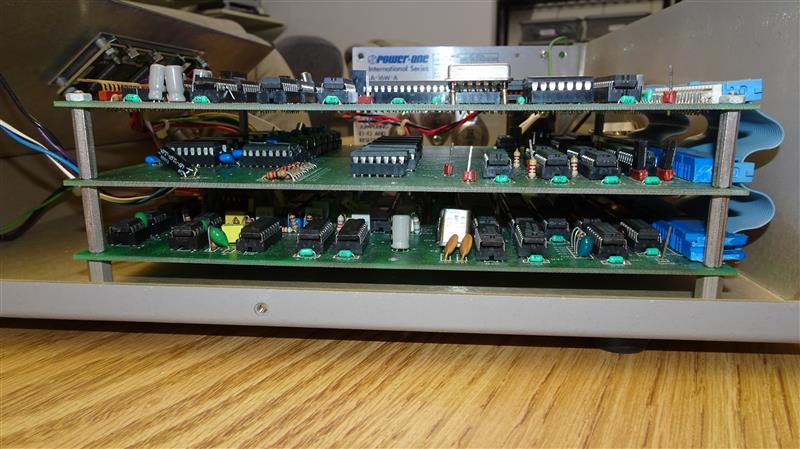

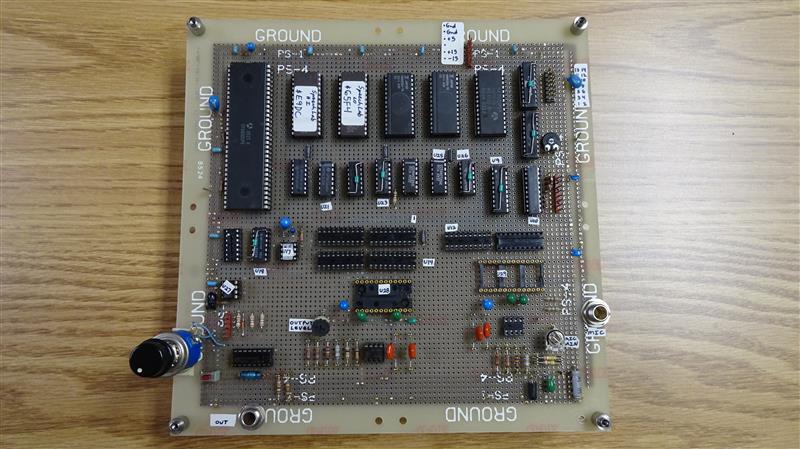

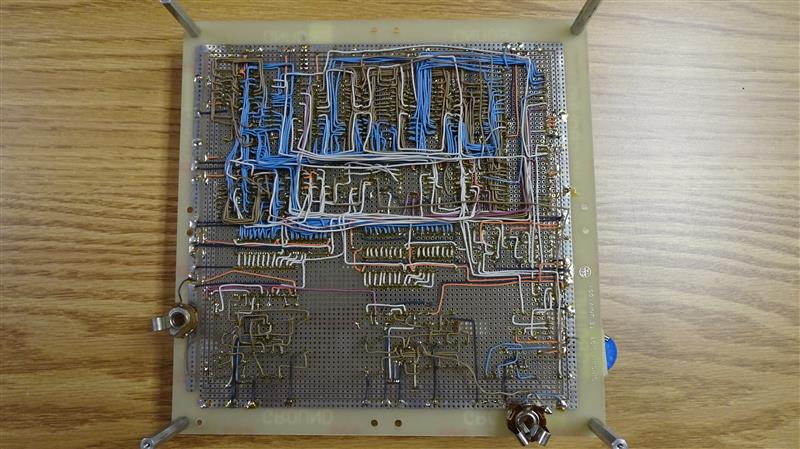

Coincidentally I was already doing a hobby project experimenting with hi-sample rate audio in order to do weird voice & guitar special effects. I called the unit Audio Machine and the first software “68000 effects unit”. This was all hand-wired (see photos). Even though there was limited RAM, I could use this unit to start writing SpeechLab type functionality to demonstrate where we were going.

Unlike dictation, I wasn’t going to use compressed audio. This application must have the best audio quality possible. So, given the technology of the day, I went with 12-bit audio samples using a 12-bit A/D and D/A. For the sampling rate, I designed a Digitally Controlled Oscillator (DCO). It has fixed outputs of 12, 24 & 48KHz plus a programmable frequency. Both the A/D and D/A could be set to use any of these four clock sources independently. That way, we could do real-time pitch change.

The final design is comprised of 3 PCBs. I created my own proprietary bus structure which used dual-row right-angle male connectors on the edge of each board. That way, I could use ribbon cables with crimped-on dual-row female connectors to tie them all together eliminating the need for a backplane PCB.

The top board had the µP, EPROM, Static RAM, small EEPROM, keypad interface, serial RS232/MIDI interface and drivers for the 16 bit data bus and 23 bit address bus.

The middle PCB was the EEDRAM Bd. Since we were recording audio at fast sample rates, the only appropriate memory at the time was DRAM. It held 512Kb organized as 256K 16-bit words. Not impressive today but quite a lot of memory back then.

The bottom PCB was the “SLAudio” board. It had the DCO I mentioned earlier, had the microphone preamps, headphone drivers, A/D with opamp based input filter and D/A with opamp based reconstruction filter. There were several EEPOTs (processor controller potentiometers) and all kind of analog switches and multiplexers. It was quite complicated, but allowed wild flexibility in audio routing and control.

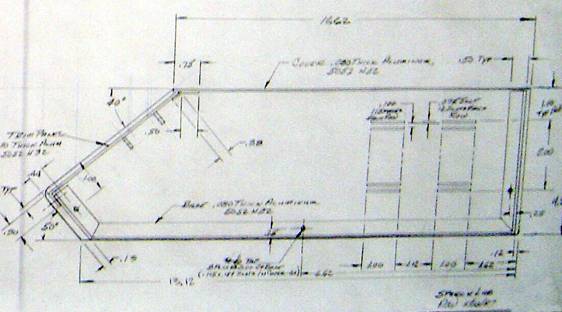

Since this was not going to be an inexpensive unit, it needed a serious enclosure. The front panel had to be sloped to allow easy viewing of the LCD and there needed to be a place for 2 LED state indicators and XLR headset connectors. I put a sketch together of what I needed, and paid a mechanical engineer at Dictaphone to do formal drawings. With these, I paid Dictaphone to produce a small run of these. We had custom labels made and the whole unit came together nicely.

We put together a one page brochure and had it printed on gloss paper. We loaned a unit to the speech therapist that was giving us the ideas for functionality. She reported great success using it with real patients. Enthused, we took it to a show and set up a booth. Lots of people tried it and complimented us, and usually said something like “I know who you need to show this to”. We followed these type of leads. At one point, we drove all the way to Florida State in Tallahassee to show it to a professor there.

In the end, we finally started to see the light. Most of the speech therapists worked in schools. The schools had a list of things they always bought and getting on it was nearly impossible. They would rather throw another stack of overhead projectors in the closet than buy anything different. Speech therapists in private practice, while even more likely to see the benefits, ended up telling us that our unit would speed up therapy and they get paid by the hour. Also, they make the same money whether they bought our unit or not. So, like every other venture, I had a design success but a total financial failure.

|

|

Electronics - Products & Misc. (page 2) |

|

SpeechLab (1987) |

|

Early hand-wired “Audio Machine” hobby project I used to get SpeechLab experiments off the ground. |

|

Enclosure Drawing |